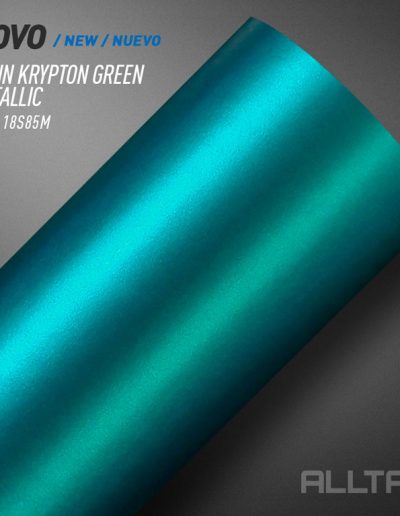

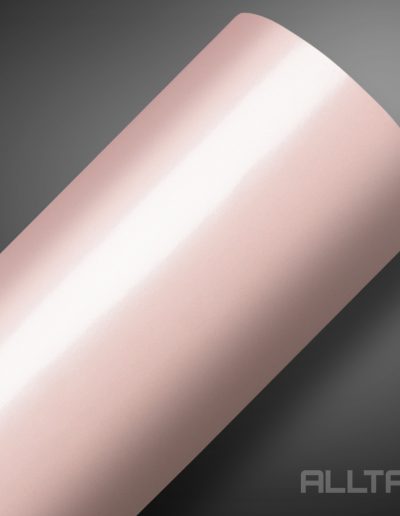

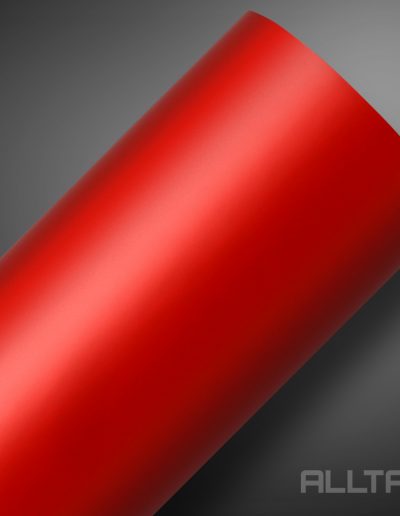

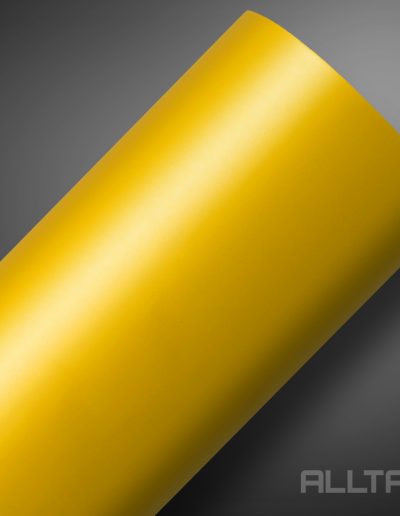

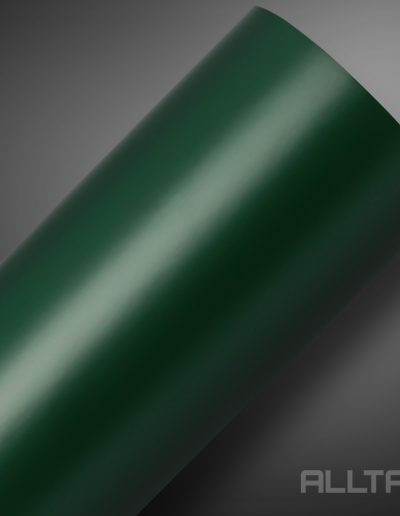

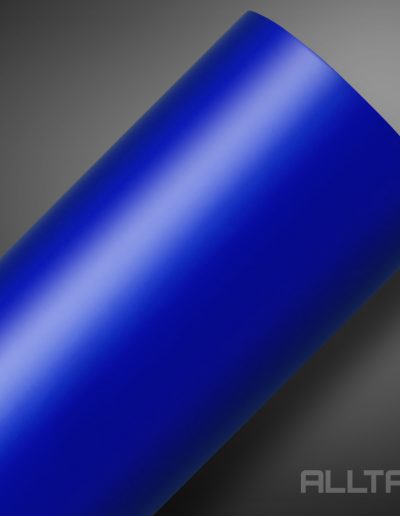

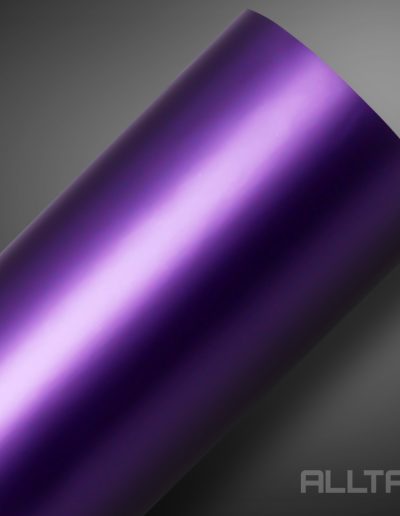

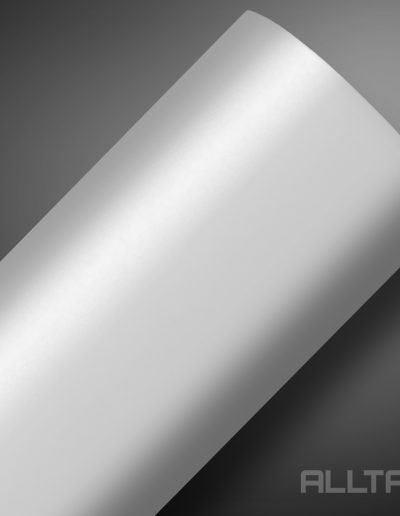

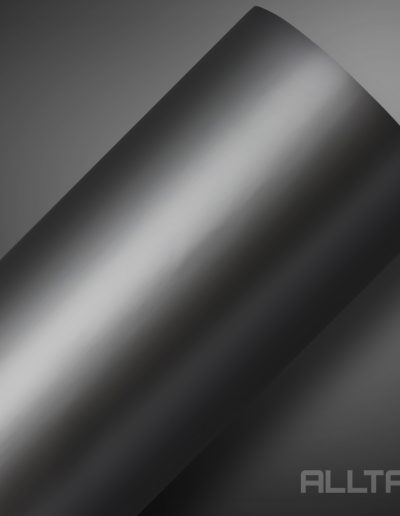

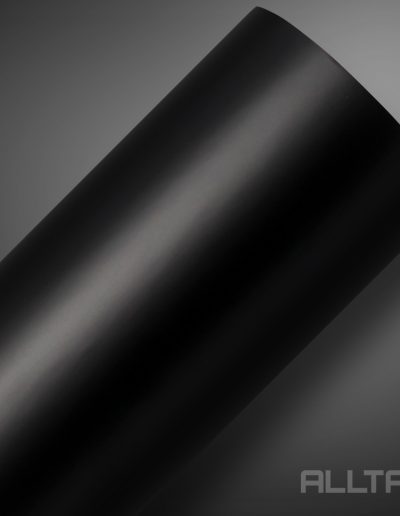

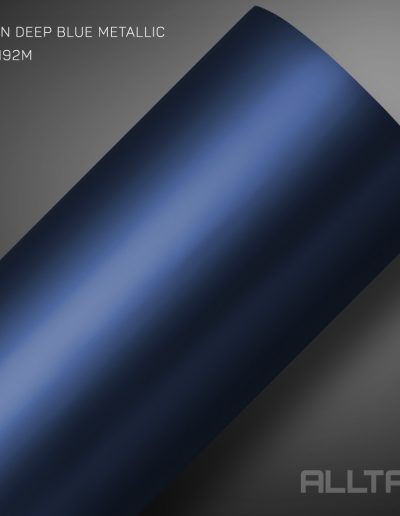

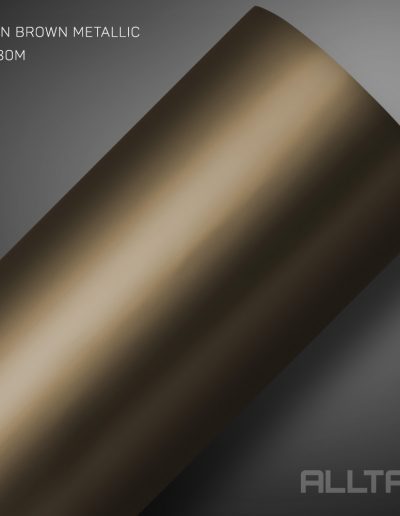

SATIN

The SATIN vinyl belongs to the ALLTAK TUNING product line. It is a satin-textured POLYMERIC calendered PVC film, available in 12 colors: white, yellow, orange, red, pink, blue, military green, metallic silver, metallic graphite, pearl white, pearl pink (mary kay), and metallic purple. Silicone coated paper release liner and repositionable acrylic adhesive. For SATIN PEARL WHITE, only a pearly white with a satin-look color is available.

Designed for vehicle protection and personalization, it can be used for decal. SATIN and SATIN PEARL WHITE have a good stability on smooth and curved surfaces, being resistant to light impacts.

SATIN PEARL WHITE: Polymeric calendered PVC film with 160 microns (0.16μm);

Release liner: SATIN: silicone coated paper with 150g/m²;

SATIN PEARL WHITE: silicone coated paper with 130g/m².

Adhesive: Repositionable acrylic adhesive with 17g/m² (+ 2g/m²).

Store it at temperatures between 20 and 30 °C, with relative humidity between 40% and 50%.

Expiration: 2 years from the date of manufacture, being stored in the original packaging and in an appropriate place.

Expected durability: for SATIN: 5 years for external use;

For SATIN PEARL WHITE and SATIN metallic colors: 1 year for external use;

The durability is reduced to 30% if horizontally applied. It can also be extended or decreased due to application and conservation techniques.