ULTRA

CAR PROTECTION AND CUSTOMIZATION FILM

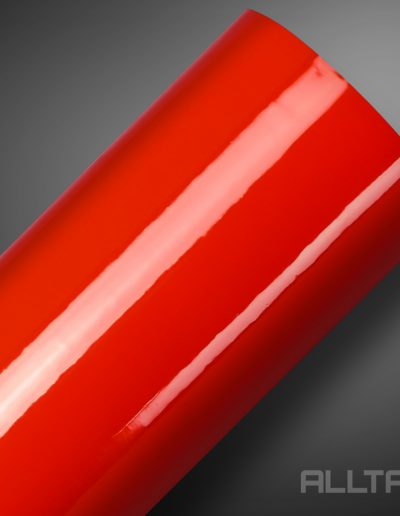

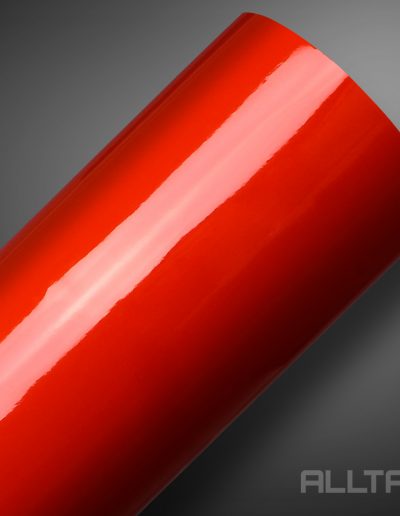

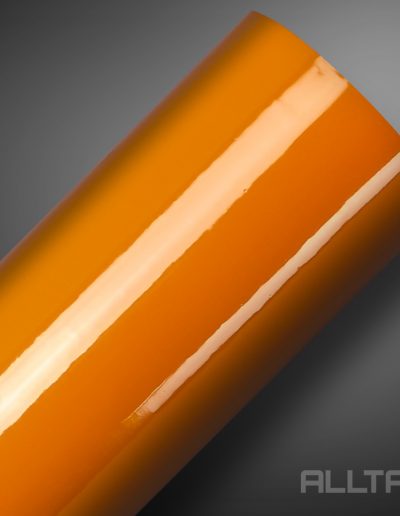

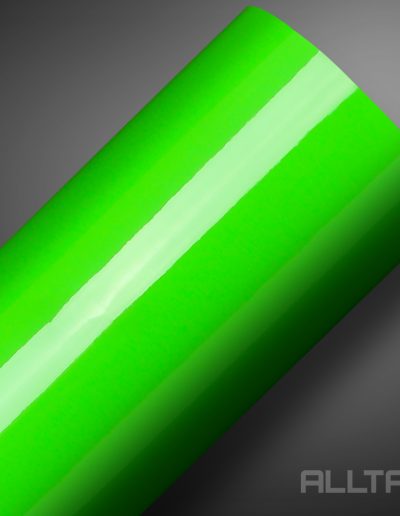

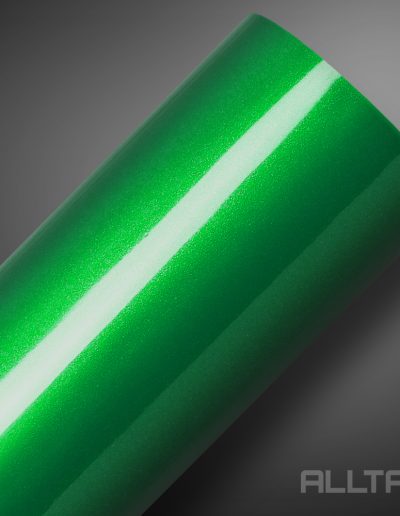

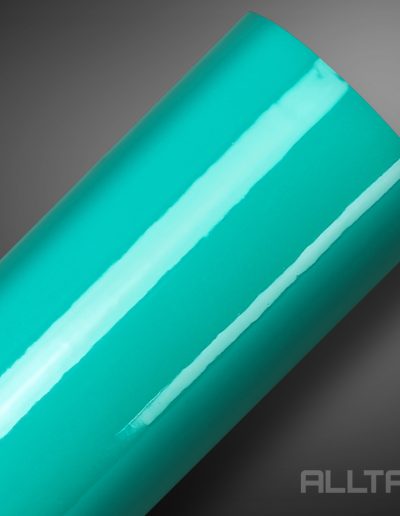

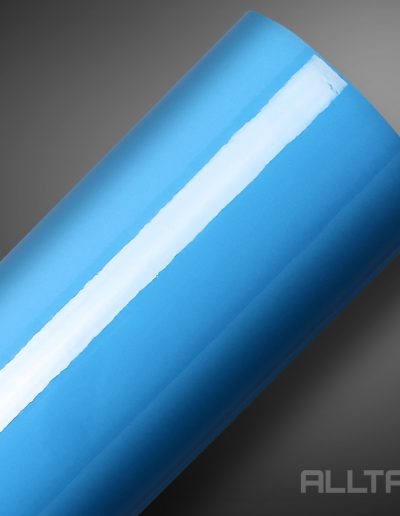

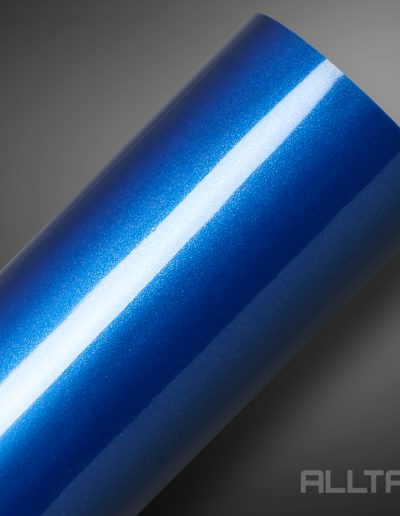

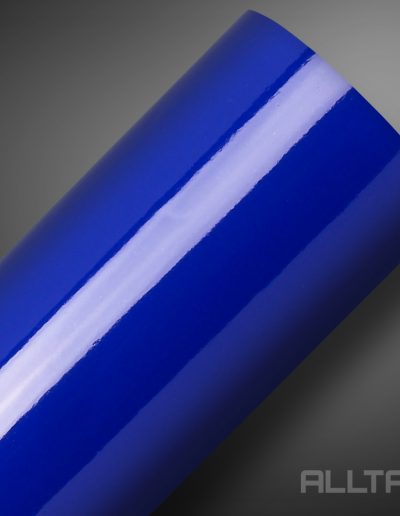

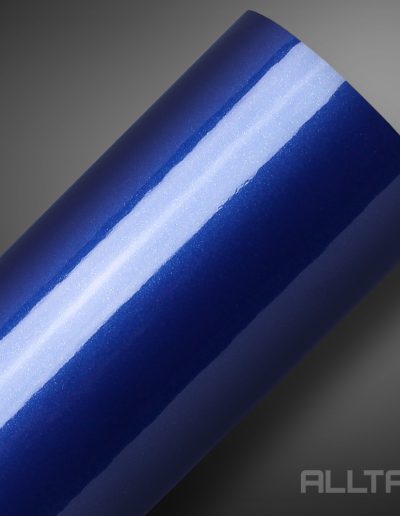

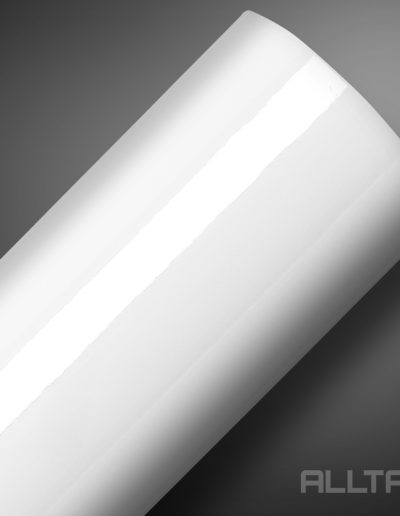

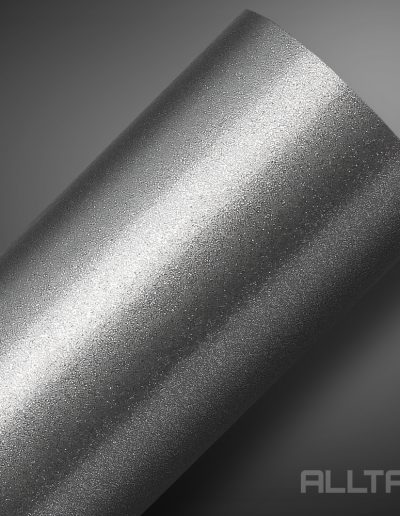

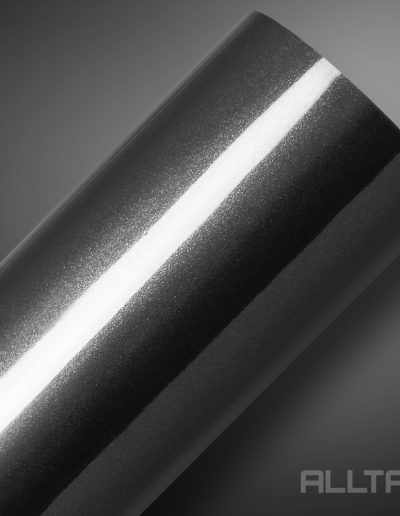

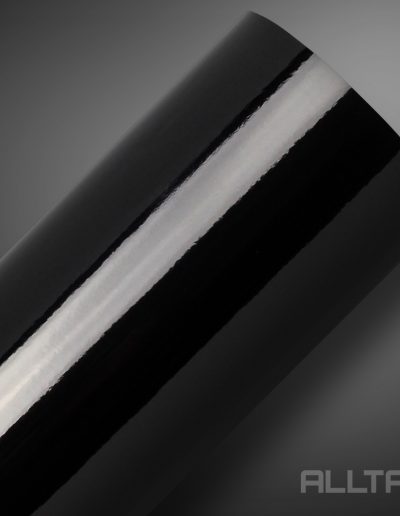

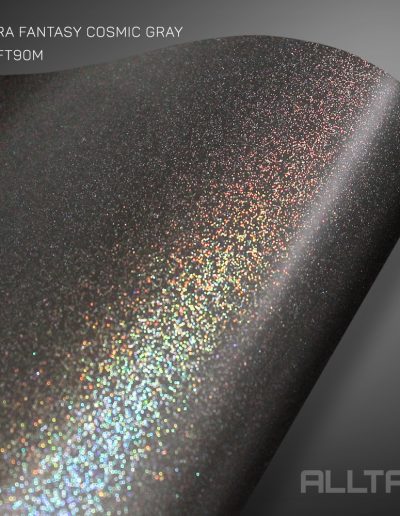

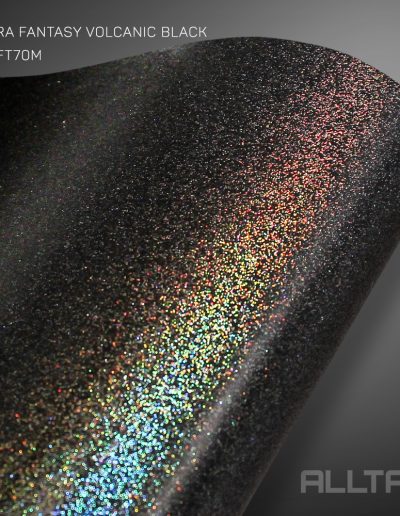

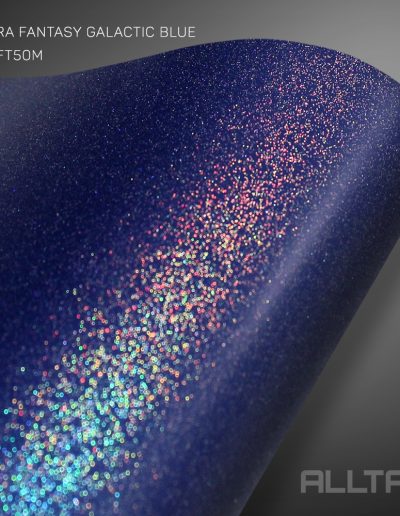

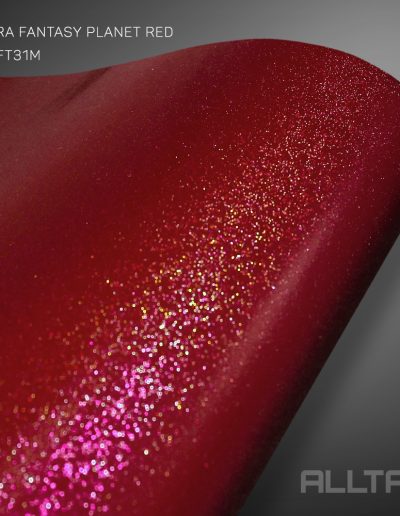

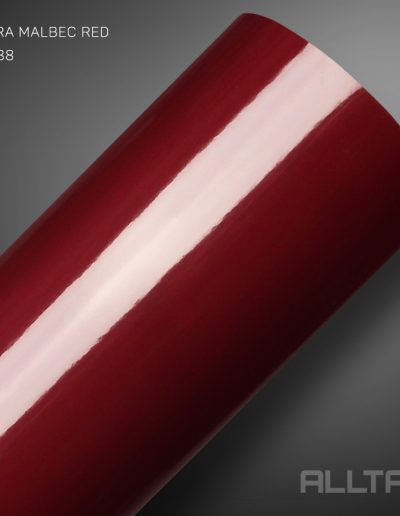

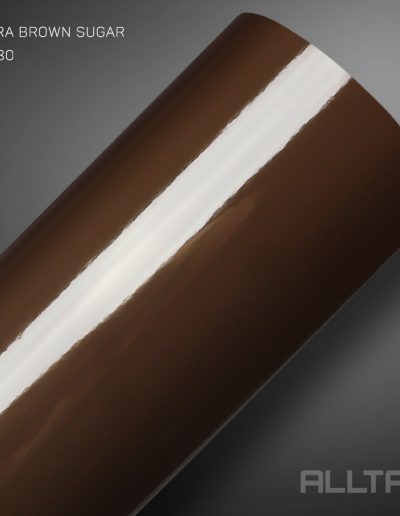

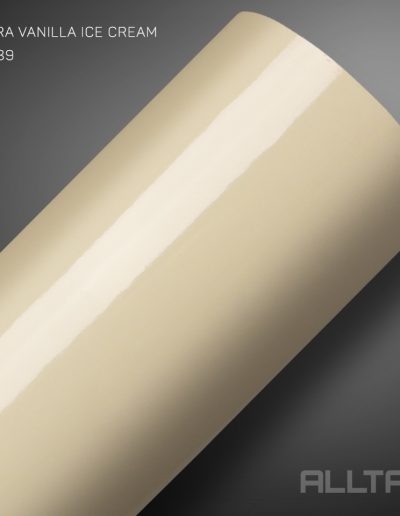

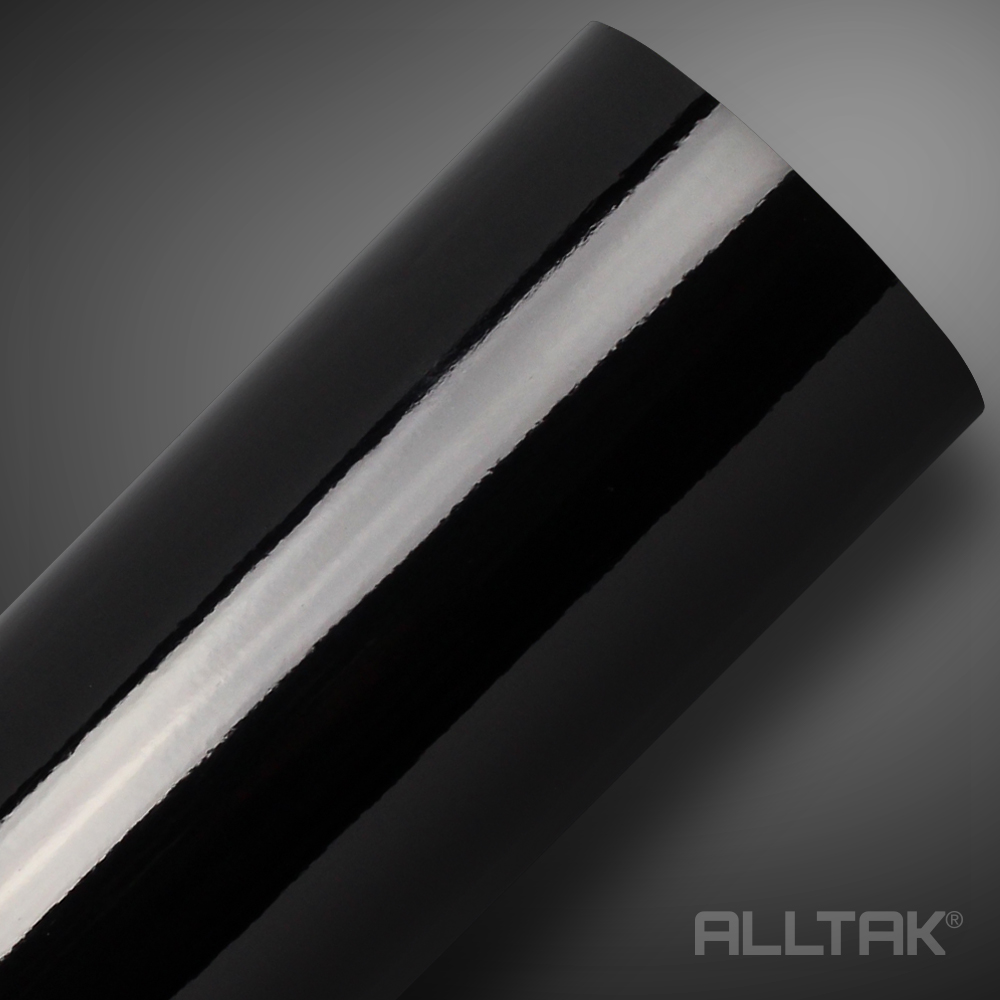

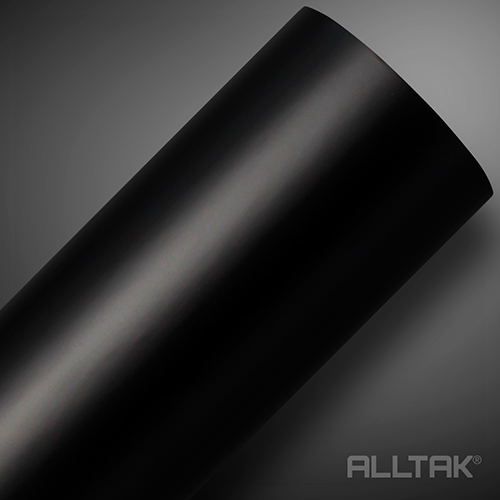

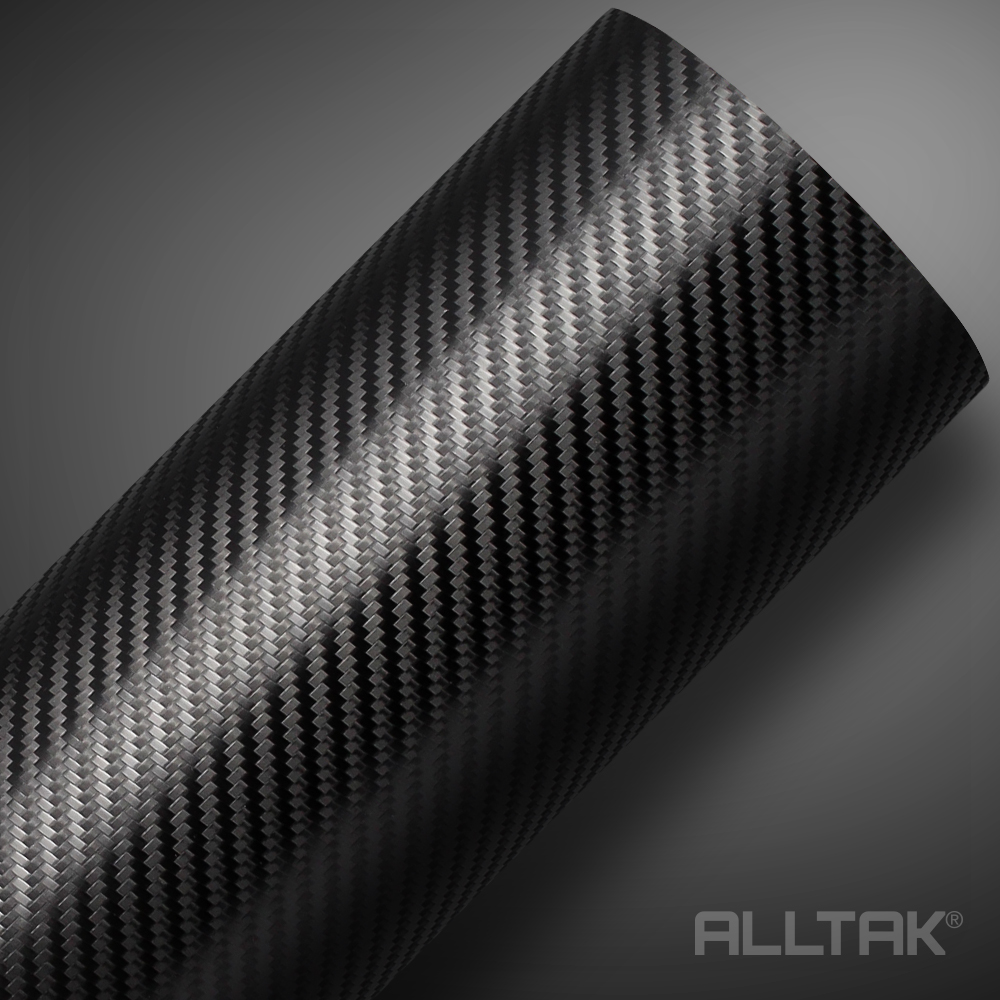

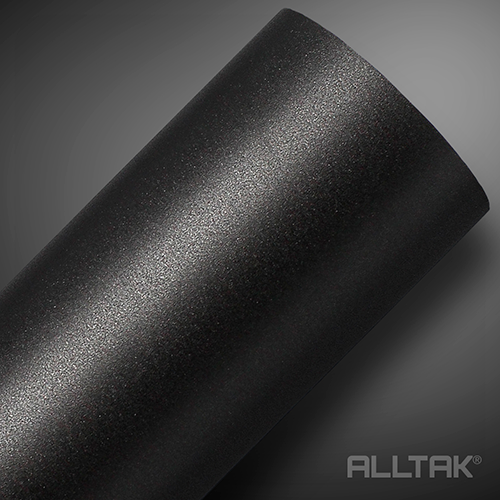

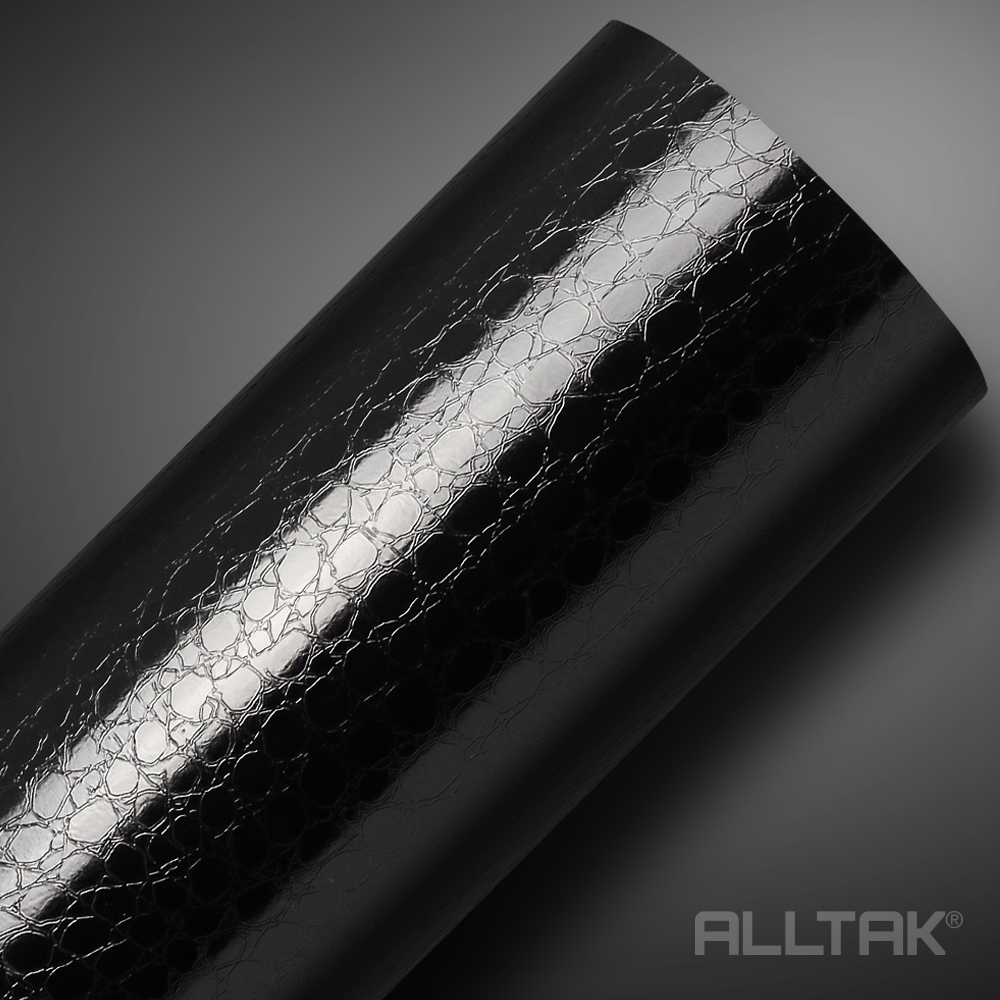

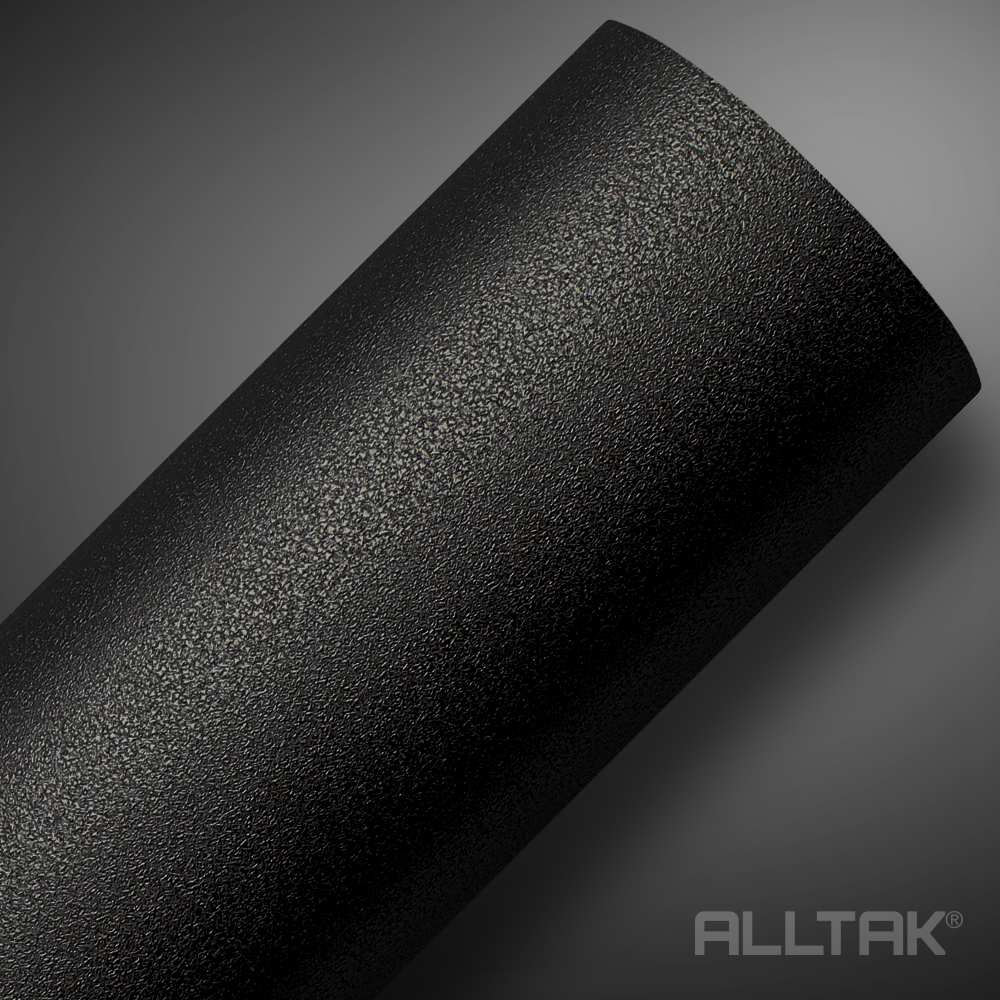

The ULTRA vinyl belongs to the ALLTAK TUNING product line. It is a high-gloss POLYMERIC calendered PVC film, available in solid and metallic colors: coconut white, piano black, mystique blue, turquoise green, Sunrise tangerine, baby blue, spicy red, banana yellow, light silver, metallic green, metallic blue and metallic graphite, and metallic deep blue. ULTRA FANTASY (metallic volcanic black, metallic cosmic gray, metallic galactic blue, and metallic planet red). ULTRA FLAKE (metallic silver and metallic gray). Silicone coated paper release liner and repositionable acrylic adhesive.

The ULTRA vinyl belongs to the ALLTAK TUNING product line. It is a high-gloss POLYMERIC calendered PVC film, available in solid and metallic colors: coconut white, piano black, mystique blue, turquoise green, Sunrise tangerine, baby blue, spicy red, banana yellow, light silver, metallic green, metallic blue and metallic graphite, and metallic deep blue. ULTRA FANTASY (metallic volcanic black, metallic cosmic gray, metallic galactic blue, and metallic planet red). ULTRA FLAKE (metallic silver and metallic gray). Silicone coated paper release liner and repositionable acrylic adhesive.

TECHNICAL SPECIFICATIONS

It is a high-gloss POLYMERIC calendered PVC film, available in solid and metallic colors: coconut white, piano black, mystique blue, turquoise green, Sunrise tangerine, baby blue, spicy red, banana yellow, light silver, metallic green, metallic blue and metallic graphite, and metallic deep blue. Silicone coated paper release liner and repositionable acrylic adhesive.

![]() Indications

Indications

Designed for vehicle protection and personalization, it can be used for decal.

Good stability on smooth and curved surfaces, being resistant to light impacts.

Designed for vehicle protection and personalization, it can be used for decal.

Good stability on smooth and curved surfaces, being resistant to light impacts.

![]() Physical properties

Physical properties

Front: polymeric calendered PVC film with 100 microns (0.10 μm) for ULTRA, 150 microns (0.15 μm) for ULTRA FANTASY and 190 microns (0.19 μm) for ULTRA FLAKE.

Release liner: Silicone coated paper with 150g/m² for ULTRA and ULTRA FANTASY, and 130g/m² for ULTRA FLAKE.

Adhesive: Repositionable acrylic adhesive with 17g/m² (+ 2g/m²).

![]() Storage

Storage

Store it at temperatures between 20 and 30 °C, with relative humidity between 40% and 50%.

Expiration: 2 years from the date of manufacture, being stored in the original packaging and in an appropriate place.

Store it at temperatures between 20 and 30 °C, with relative humidity between 40% and 50%.

Expiration: 2 years from the date of manufacture, being stored in the original packaging and in an appropriate place.

![]() Supply and durability

Supply and durability

Item packaged in cardboard box and reels with a width of 1.38m for ULTRA, 1.35m for ULTRA FANTASY, and 1.22m for ULTRA FLAKE.

Expected durability: 5 years for external use (except metallic, ultra flake and ultra fantasy colors: 1 year); this durability is reduced to 30% if horizontally applied. It can also be extended or decreased due to application and conservation techniques.

Item packaged in cardboard box and reels with a width of 1.38m for ULTRA, 1.35m for ULTRA FANTASY, and 1.22m for ULTRA FLAKE.

Expected durability: 5 years for external use (except metallic, ultra flake and ultra fantasy colors: 1 year); this durability is reduced to 30% if horizontally applied. It can also be extended or decreased due to application and conservation techniques.

![]() Instructions

Instructions

Apply it on a clean and flat surface previously cleaned with isopropyl alcohol, thus avoiding the contact with impurities, oils or any other chemical;

The application on corrugated, rough and/or porous surfaces is not advised;

The excessive use of solvent decreases the product’s durability;

Install it immediately after cutting;

After applying it, avoid aggressive products and constant friction, and use a neutral soap.

Apply it on a clean and flat surface previously cleaned with isopropyl alcohol, thus avoiding the contact with impurities, oils or any other chemical;

The application on corrugated, rough and/or porous surfaces is not advised;

The excessive use of solvent decreases the product’s durability;

Install it immediately after cutting;

After applying it, avoid aggressive products and constant friction, and use a neutral soap.

CONHEÇA TODA LINHA DE ENVELOPAMENTO